Hello, guys What are the 3 advantages of CAD and 5 disadvantages of CAD and Applications of CAD advantages and disadvantages, Benefits of CAD and advantages of CAD over manual drawing?

Do you know what are the 3 advantages of CAD?

1. Better Quality

It’s implied that plan programming can produce stylishly satisfying drawings other than having added usefulness.

It likewise gives the client an immense number of devices to make the drawing as similar as envisioned.

Computer–aided design has different benefits over manual drawings that have made it outright fundamental in the plan market today.

We should investigate how they help contemporary specialists or item planners.

Let’s see what are the pros of learning AutoCAD.

2. Builds Productivity

Time-saved interprets straightforwardly into expanded efficiency.

A similar measure of time can bring about a larger number of finished projects.

The repeatability of configuration is a choice.

Altering a similar plan is feasible to make limitless varieties of the eventual outcome.

All things considered, a 3x expansion in representative efficiency is taken note of. With time, this efficiency can approach 10x.

An enormous piece of it boils down to the capacity to make reenactments in CAD as opposed to doing manual computations.

This improvement is seen on different fronts like quality, time, and cost decrease in assembling.

3. Further develops Accuracy

Manual outlining can’t compare to the precision of CAD drawings. Computer-aided design plan’s precision is unmatched with basically no blunders.

This gives it a gigantic benefit over manual planning and drafting.

The architect should in any case focus on the result.

The “recover aspects” capability doesn’t supplant an architect, as it doesn’t perceive the base planes for estimations, for instance.

Also, this can be significant with parts like shafts.

Complex surfaces and shapes can be made nearly effectively in CAD.

These surfaces are very challenging to get right with a manual outlining yet with CAD frameworks’ devices, an ideal outcome can be gotten.

4. Diminishes Errors

Elements, for example, obstruction checking (which likewise has a place with our rundown of designing tips) for 3D models offer benefits extraordinary to CAD frameworks.

This component assists the creator with checking for impedances between at least one section.

A simple method for diminishing blunders

It is not difficult to change the size of an opening, go for an espresso, and later neglect to in like manner decrease the size of the pin.

We can now ensure that the pin will squeeze into the entire by utilizing this capability of the CAD framework.

5. Saves Time

The continuous time of item improvement involves a great deal of rivalry.

The time it takes to put up an item for sale to the public can be fundamental for its prosperity.

With CAD, time is our worthwhile award.

It saves the specialist a ton of work that can be effectively utilized on various tasks or culminating the plan of the continuous one.

You can without much of a stretch envision the thoughts you assembled during the item plan idea age stage.

Making straightforward shapes and parts requires seconds.

The greatest success, however, accompanies more perplexing parts.

For instance, you can make a level example of a mind-boggling bowed sheet metal part with a tick of a mouse.

Don’t bother thinking about how to accurately introduce it.

Simultaneously, it is truly simple to make changes.

Or on the other hand, making new models in light of past ones.

You can just re-utilize a 3D model and add the fundamental elements to make a comparable yet one-of-a-kind part in much less time.

6. Recover aspects rapidly

Indeed, even the trickiest of items can be made with the right information on accessible instruments and the necessary numerical conditions.

This adaptability allows the creator to break new ground and think of inventive arrangements without the apprehension about not having the option to write the thought down.

Higher readability and fewer mistakes in drawings likewise bring about better quality and more exact results.

7. Simplicity of Understanding

The accessibility of 3D models to go with drawings can make even the most troublesome drawings simple to appreciate.

This isn’t possible in that frame of mind as at least three representations (plan, rise, and side view) would be expected to get an overall thought.

Different perspectives, for example, isometric or segment perspectives may likewise come into the image.

While CAD is entirely adequate at showing the above perspectives on an item, nothing beats having the option to mess with the item in the virtual space to grasp its careful designs.

Numerous studies today utilize this chance by giving machine administrators and constructing agents tablet PCs to make the work more straightforward.

Computer-aided design models additionally make it simpler for planners to feature their items to individual fashioners as well as laymen who have no establishment in designing.

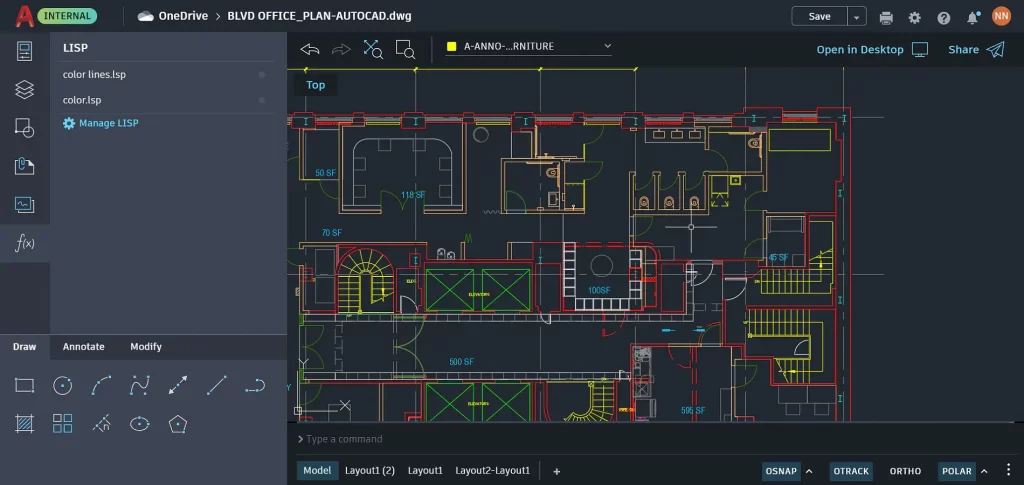

8. Fast Sharing for Collaboration

Computer-aided design drawings, being advanced documents, are not difficult to divide between colleagues who are chipping away at a similar item.

Sharing is momentary. Hence, even far-off representatives can remain in the know about any improvements with no issue.

With quicker web turning into a customary office, CAD programs are presently being utilized on the cloud. Hence, the sketch stays open consistently to indicated colleagues for simple surveys and adjustments.

This is an incredible benefit for organizations that have various field workplaces spread across the globe.

Computer-aided design-created models additionally have normalized designs.

This gives consistency in plan devices and images and permits various clients to chip away at similar ventures with next to no obstacles.

9. PC Aided Manufacturing (CAM)

Making CAD or CAE (Computer-Aided Engineering) models likewise assists with placing parts into creation a lot quicker.

Computer-aided design CAM programming makes it simple to check the apparatus ways for CNC machining and feed the documents to the machines.

Computing CNC machining costs considering process durations and utilizing CAM frameworks makes it a lot more straightforward and quicker.

Such programming makes the essential machine code for creation just in light of the model.

The greatest benefit is obvious for CNC machining administrations where the entire any other way troublesome interaction can be generally computerized, including the difference in devices.

10. Joining ERP

Having the option to utilize CAD/CAM likewise permits architects to integrate the records into an ERP framework.

ERP is an abbreviation for Enterprise Resource Planning.

In assembling, ERP is utilized to improve the proficiency of any cycle.

An ERP programming coordinates and directs various features in an undertaking so that less time is expected to go from natural substances to completed items.

11. Advantages of Automation

The answer to limiting undertaking lead time is to mechanize all common cycles in the planning stage.

Computer-aided design utilization chops down a ton of snort work that is a piece of manual drawing, without influencing the quality.

For example, organizations offering custom items have the expanded strain of making proposition reports and drawings as quickly as could be expected.

Most realistic estimation costings are normal for orders that are not ensured. Designing offices’ assets are squandered on errands that can be computerized.

On consolidating computerization, additional time is accessible to develop and increase the value of the item.

One such way is to get computerized creation quotes with cloud fabricating specialist organizations.

This fundamentally lessens the time spent on obtainment cycles and gives a cost in a split second based on CAD models.

This way architects can, thus, quote their clients. Such speed can frequently win a task.

Through CAD, various pieces of a similar item can be made independently and joined in the last stage.

These elements increment throughput, decrease mistakes, and work on quality permitting you to take on more business out of nowhere.

There are many kinds of CAD programs out there.

The most famous one is presumably SolidWorks, with Inventor and Solid Edge following intently behind.

These projects are less adaptable however their usefulness is all that anyone could need to begin learning.

I hope you like this article What are 3 advantages of CAD?

Read More: Introduction to AutoCAD. and How to use the AutoCAD command line.

What are the advantages and disadvantages of CAD?

| Disadvantages of CAD | Advantages of CAD |

|---|---|

| Needs a gifted labor force | Plans can be seen from all points and with a scope of materials |

| PCs can fall flat | It becomes simpler to plan and test the scope of thoughts |

| Hard to stay aware of continually changing and further developing innovation | A few testing and buyer input should be possible before exorbitant creation happens |

| Costly to set up | Thoughts can be drawn and grown rapidly |

What are the 3 advantages of CAD CAM?

1. CAD CAM software is a very time-saving product.

2. Computer-aided design CAM designing programming permits us to incorporate straightforwardly with the CNC turning and processing plant.

The nearby mix of the plan and assembling process lessens the hole between the two cycles.

It additionally permits the machines to be utilized most proficiently.

3. The utilization of CAD-CAM applications hugely increments the command over the creation cycle, which when utilized for CNC processing can mean a critical expansion in exactness.

Conclusion of What are 3 advantages of CAD

Drawing has a spot in the planned business.

Numerous originators start with an unpleasant manual draft of the item before moving on to CAD.

However, with regards to the current item showing, portraying simply doesn’t cut it any longer.

Computer-aided design has introduced a time of expert plan that is so flexible, speedy, and healthy that it can’t be disregarded any longer.

To try not to involve CAD in this time is similar to going against the flow and consequently, a benefit looking for adventure can’t bear to miss out on the advantages of CAD.

Thank you for reading are 3 advantages of CAD article.

FAQ on What are 3 advantages of CAD

Dispose of Costly Mistakes and Waste. Computer-aided design CAM programming gives strong reproduction highlights.

Reproduction permits you to outwardly examine the machining system, and get expensive device gouges and crashes before they arrive at the CNC machine.

This by itself makes adding a CAD-CAM item to the shop a decent choice.

1. High creation or buying cost for new framework systems.

2. Time & cost of preparing the staff which will chip away at it

3. Work can be lost as a result of the unexpected breakdown of personal computers or Laptops.

You can Read our Other Articles

- What is AutoCAD Electrical? (99% want to Know) APR 2024

- AutoCAD Student Teacher Watermark (99% A-Z Tips) APR”24

- AutoCAD Earth Ground Symbols (70% Don’t Know) April”24

- What Computer language was AutoCAD written in? (90% Don’t Know)

- Best 11 laptops for AutoCAD 2024 (100% You Like) Apr”24

- Autodesk Takeoff 2024 | 80% of People Don’t Know (April”24)

- AutoCAD Section Line | 100% You Don’t Know April 2024

- AutoCAD shortcut keys (80% New keys don’t Miss) April 2024

- AutoCAD 2024 software price in India (99% it’s Confusing) Apr”24

- How to Autodesk clear temp files? (100% Legit Tips) Apr”24

Leave a Reply